Boost Your Bottom Line with the PACER by Cimarron Tank

Reclaim and reuse spent glycol

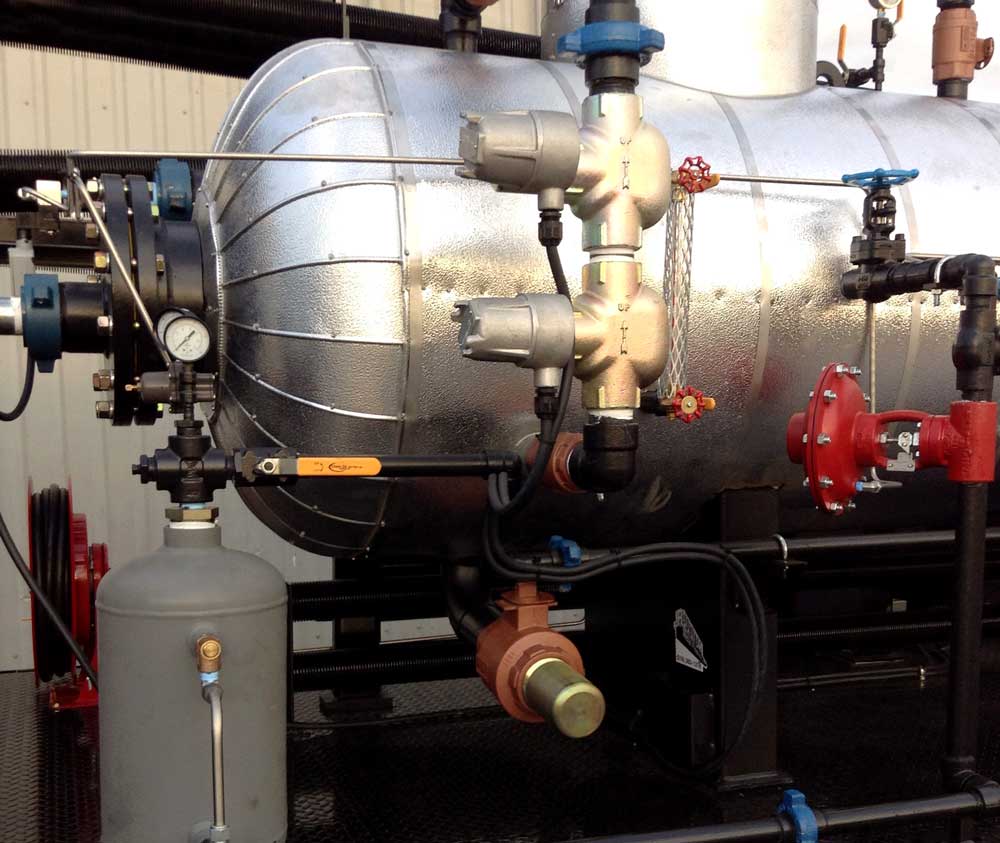

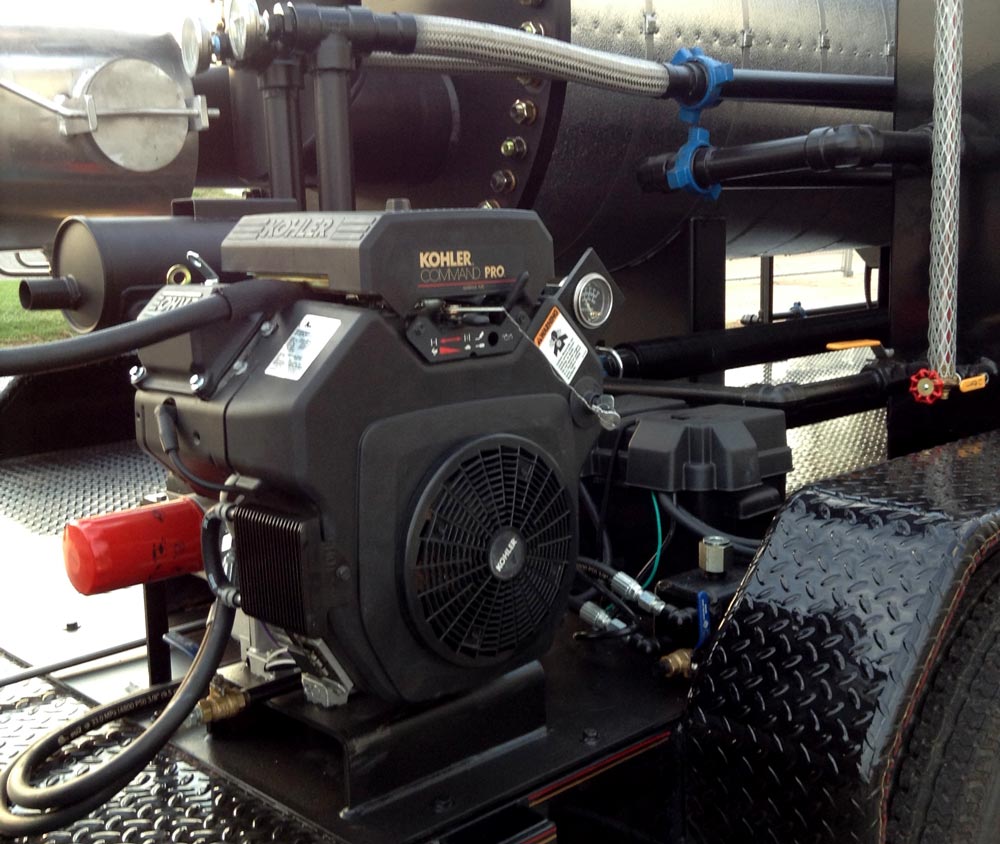

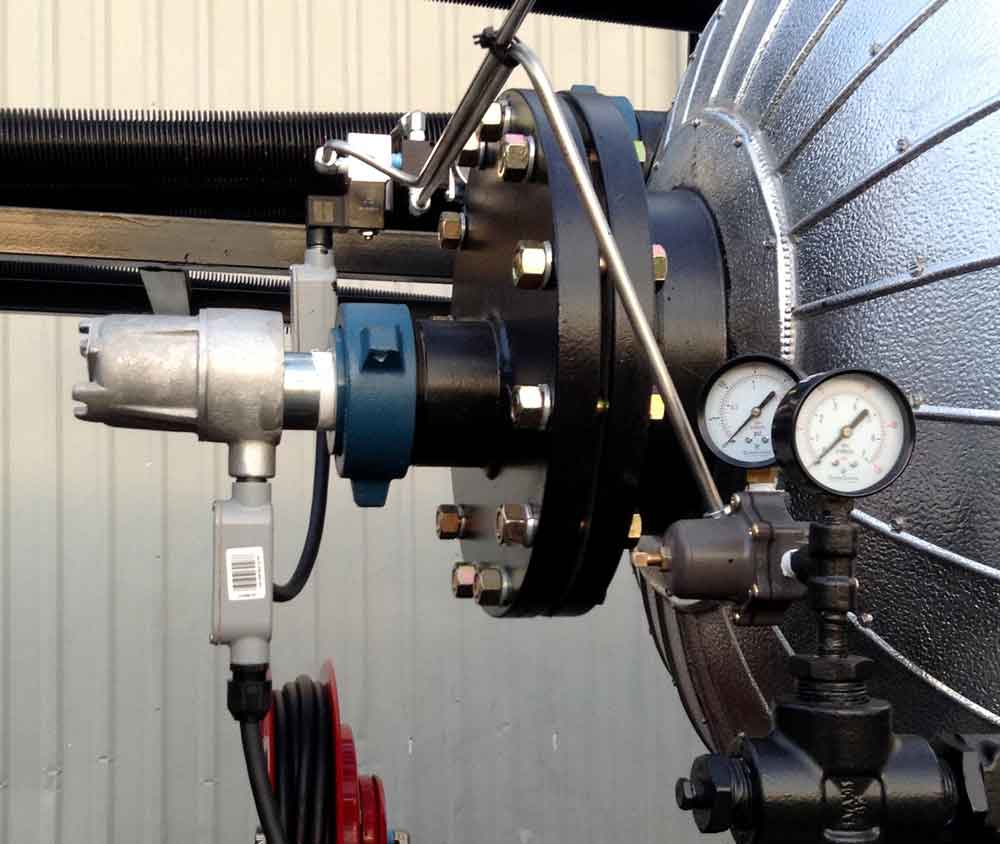

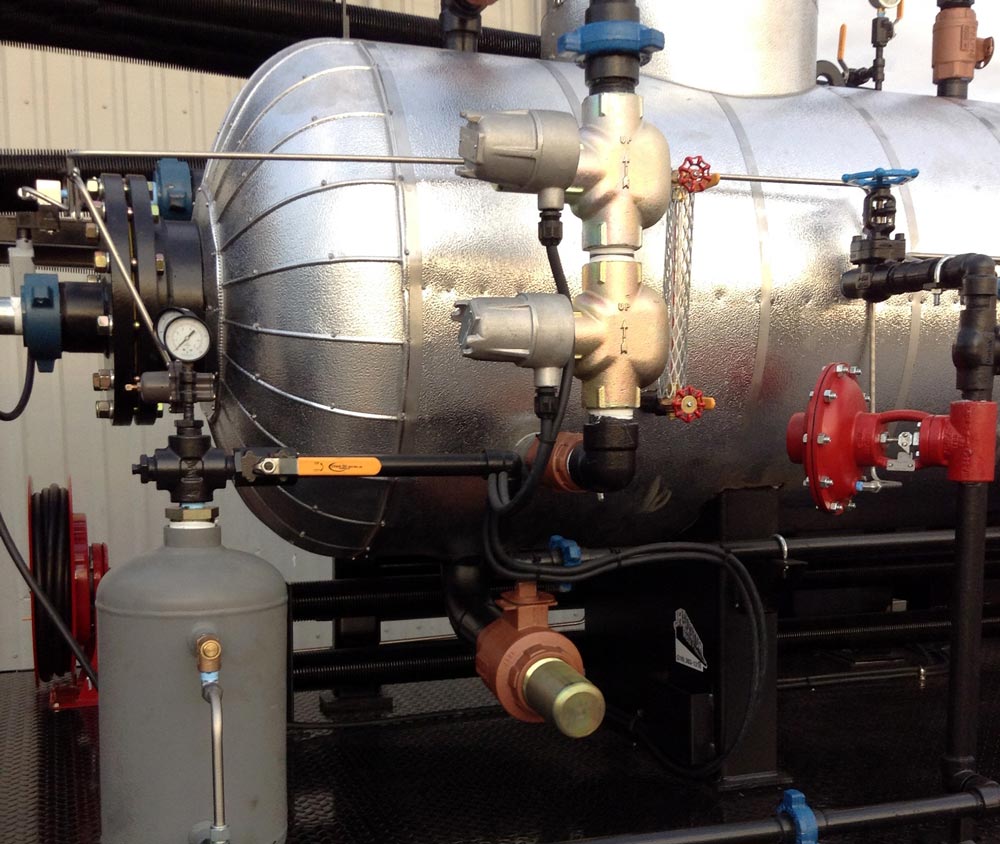

Keep your dehydrators online and reduce your glycol budget by up to 90 percent. The PACER’s patented vacuum distillation technology cleans the glycol in a single cycle while the dehydrator unit continues to operate. Whether as a sidestream system or connected to a holding tank, the PACER delivers results that make a bottom-line impact.

Remove unwanted particulates

The PACER utilizes the glycol in the dehydration system to aid in the removal of chlorides, sludge, dissolved solids and other contaminants that cause glycol to lose effectiveness and add to costly maintenance procedures.

Plan preventative maintenance on your schedule

Improve the efficiency and life of your dehydrator systems with the PACER. The PACER cleans both the glycol and the dehydrator unit, combining mechanical maintenance with glycol purification. Keep your operation online and running smoothly while the PACER preserves your equipment.

Reduce environmental impacts

From lower dew points to reduced BTEX and VOC emissions, the PACER will reduce your operation’s environmental impact. Surpass harsh federal and state regulatory requirements and lower your reliance on environmentally unfriendly waste disposal by 97 percent.

Transport your unit quickly and easily

The PACER by Cimarron Tank is a self-contained, portable system that can be taken to virtually any dehydration site. Operators gain the flexibility to move the PACER quickly and easily wherever they need it – production site, processing, transmission and storage.